Payment Type:L/C,T/T,D/P,Paypal

Incoterm:FOB,CFR,CIF,EXW

Min. Order:1 Set/Sets

Transportation:Ocean,Land

Port:Zhongshan,Shenzhen,Nansha

$5000≥1Set/Sets

Model No.: Tooling

Brand: Nil

Place Of Origin: China

Status: New

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Plc

Warranty Period: 1 Year

Out-of-warranty Service: Video Technical Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Applicable Industry: Other, Manufacturing Plant

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

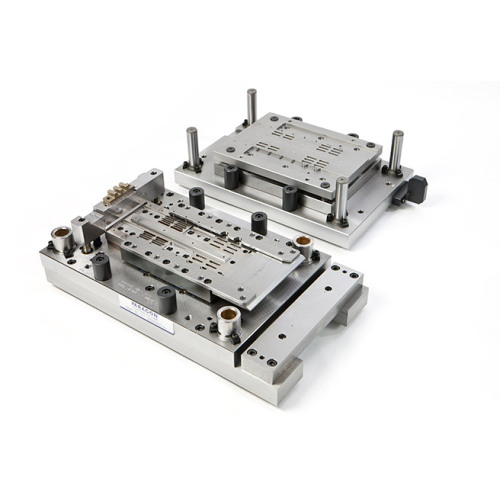

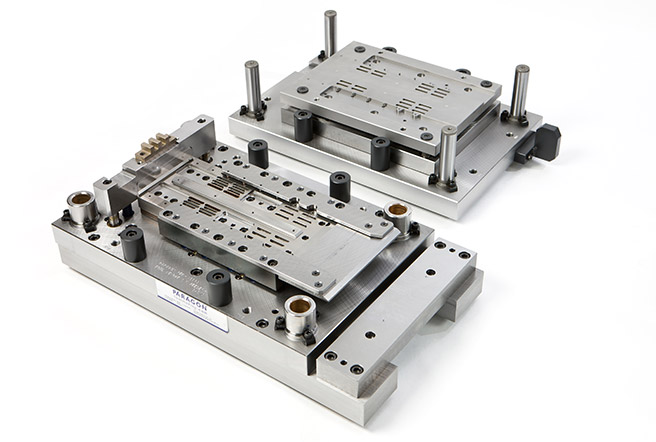

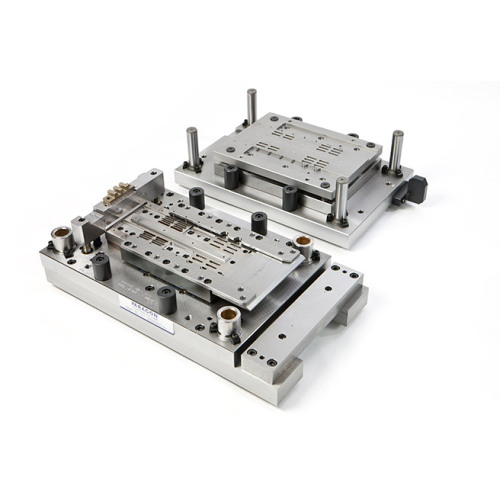

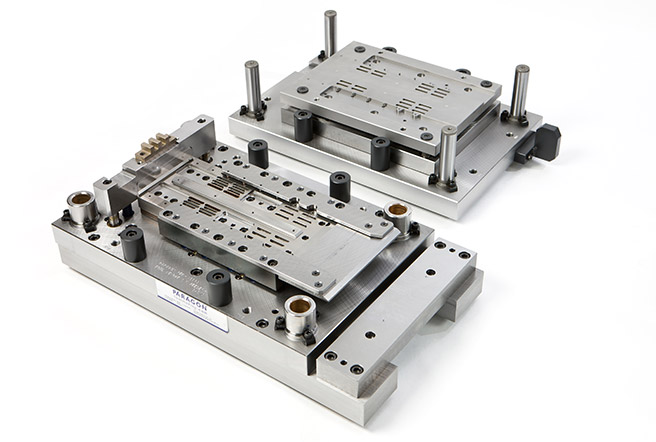

100 - 1,800 Tons: Plastic injection tooling

Packaging: Wooden Case

Productivity: 1000

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: Production time 30 - 60 days

Certificate: ISO9001

HS Code: Custom manufacturer of plastic injection molding tooling. Pr

Port: Zhongshan,Shenzhen,Nansha

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW

Custom manufacturer of plastic injection molding Tooling. Products include prototype and bridge molds, two, three and four level stack molds, unscrewing molds, spin stack molds, gas -assist molds and multi-shot molds. Plastic injection battery molds, two-shot molds, multi-cavity molds, stack molds and insert molds can be fabricated. Capabilities include product design and development, mold flow analysis, mold repair, engineering and contract measurement.

Custom plastic injection moulding is a manufacturing process that involves creating custom Plastic Parts or products by injecting molten plastic into a mould. The mould is typically made from steel or aluminum and is designed to the exact specifications of the desired product.

The process begins with the creation of a 3D design or CAD model of the product. This design is then used to create a mould, which is divided into two halves to allow for the injection of plastic. The mould is precision-machined to ensure accuracy and quality.

Once the mould is ready, the plastic material is heated until it becomes molten. It is then injected into the mould under high pressure, filling the cavity and taking on the shape of the desired product. The plastic is allowed to cool and solidify within the mould, after which the two halves of the mould are separated, and the finished product is ejected.

Custom plastic injection moulding offers several advantages over other manufacturing processes. It allows for the production of complex and intricate parts with high precision and consistency. It also offers a wide range of material options, including various types of thermoplastics, which can be chosen based on the specific requirements of the product.

Furthermore, custom plastic injection moulding is a highly efficient process, with fast production cycles and minimal waste. It is also cost-effective for large volume production runs, as the initial set-up costs for creating the mould can be offset by the high production output.

Overall, custom plastic injection moulding is a versatile and efficient manufacturing process that is widely used in various industries to produce a wide range of plastic products

Omni Breeze Tower Fan.Cooling tower fan.Plastic Injection Mould

We also the manufacturer of DC Swan Fan, air Circulation Fan , tower Fan, AC/DC Power Stand Fan