Payment Type:L/C,T/T,D/P

Incoterm:FOB,EXW

Min. Order:1 Set/Sets

Port:Zhongshan,Shenzhen,Nansha

$5000≥1Set/Sets

Model No.: Tooling

Brand: T-Balance

Place Of Origin: China

Status: New

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Warranty Period: 1 Year

Out-of-warranty Service: Video Technical Support, Online Support

Applicable Industry: Manufacturing Plant

Packaging: Wooden

Productivity: 1000

Place of Origin: China

Supply Ability: 45 - 60 days

Certificate: ISO9001

Port: Zhongshan,Shenzhen,Nansha

Payment Type: L/C,T/T,D/P

Incoterm: FOB,EXW

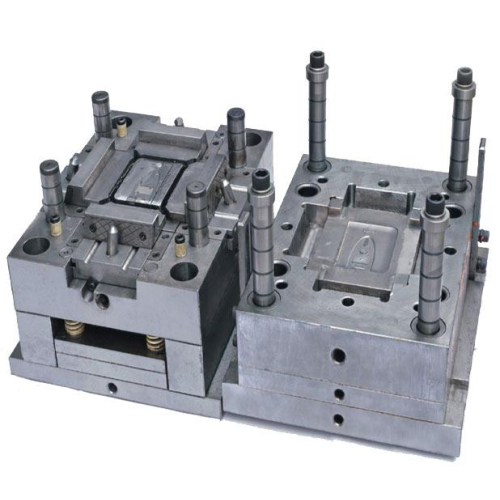

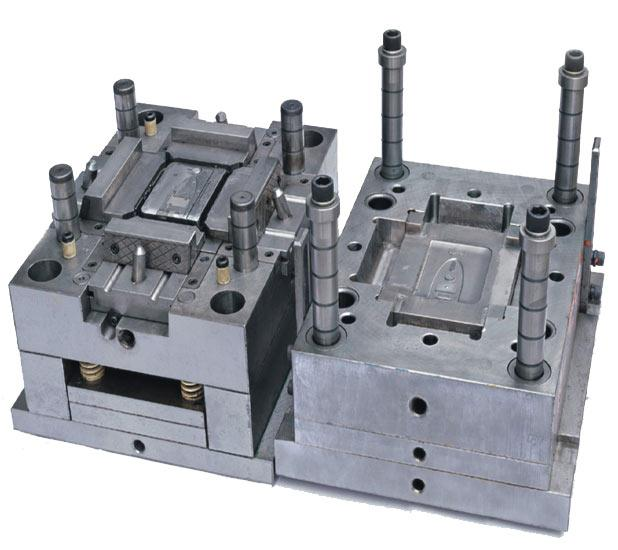

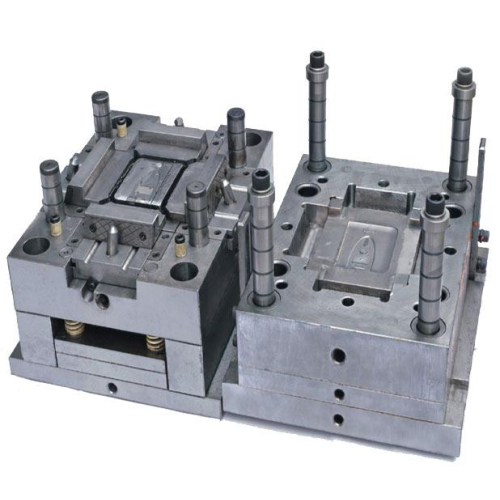

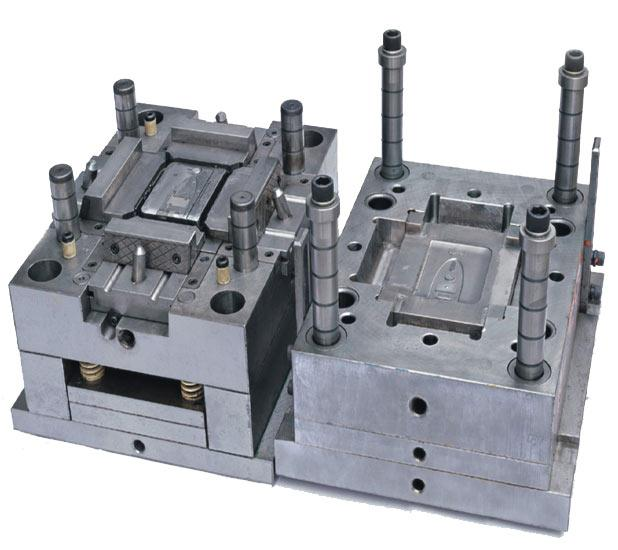

Fan Tooling refers to the manufacturing process of creating tooling for fans, which are devices used to circulate air and create a cooling effect. Fan tooling involves the design, fabrication, and assembly of various components that make up a fan, including the blades, Motor, housing, and other necessary parts. In conclusion, fan tooling is a complex manufacturing process that involves the design, fabrication, and assembly of various components to create a functional and efficient fan. It requires expertise in engineering, design, and manufacturing to produce high-quality fans that meet the needs of consumers in various industries. We also the manufacturer of DC Swan Fan, Air Circulation Fan, tower fan, AC/DC Power Stand Fan

The process of fan tooling begins with the design phase, where engineers and designers create detailed drawings and specifications for the fan components. This includes determining the size, shape, and material of the blades, as well as the type and power of the motor. Advanced computer-aided design (CAD) software is often used to create 3D models and simulate the airflow and performance of the fan.

Once the design is finalized, the fabrication phase begins. This involves the manufacturing of the individual components of the fan, such as the blades, motor housing, and base. Fan blades are typically made of lightweight and durable materials such as aluminum or plastic, and are often shaped in a way that maximizes airflow and efficiency. The motor housing is usually made of metal or plastic and is designed to securely hold the motor and blades in place.

After the individual components are fabricated, they are assembled together to create the complete fan. This involves attaching the blades to the motor shaft, securing the motor housing, and connecting the necessary wiring and controls. The assembly process requires precision and attention to detail to ensure that all components fit together correctly and that the fan functions properly.

Once the fan is assembled, it undergoes rigorous testing to ensure its performance and safety. This includes testing the airflow, noise levels, and power consumption of the fan, as well as checking for any potential defects or malfunctions. Any necessary adjustments or modifications are made to improve the fan's performance and reliability.